Alle producten

-

Ceramische Kogellagers

-

608 Ceramische Lagers

-

Hybride Ceramische Lagers

-

Ceramische Rollagers

-

Ceramisch Duwlager

-

Het ceramische het glijden dragen

-

Geavanceerde Structurele Keramiek

-

De Bal van het siliciumnitride

-

De Bal van het siliciumcarbide

-

Zirconiumdioxyde Ceramische bal

-

De Kogellagers van het siliciumcarbide

-

Het kogellager van het siliciumnitride

-

Zirconiumdioxyde Ceramisch Lager

-

Het mechanische Verzegelen

-

Het Lager van het siliciumcarbide

-

RobertaHun ceramische lagers zijn van hoge precisie, goede kwaliteit en goedkoop. Wij hebben samenwerking vele jaren.

RobertaHun ceramische lagers zijn van hoge precisie, goede kwaliteit en goedkoop. Wij hebben samenwerking vele jaren. -

Olga WeinbergDit bedrijf is onze betrouwbare en professionele leverancier van ceramische lagers vele jaren, hun ceramische lagers, die in onze pomp goed zijn in kwaliteit worden gebruikt.

Olga WeinbergDit bedrijf is onze betrouwbare en professionele leverancier van ceramische lagers vele jaren, hun ceramische lagers, die in onze pomp goed zijn in kwaliteit worden gebruikt.

Contactpersoon :

Cooper wang

Telefoonnummer :

86 15801087509

Sliding Bearing SiC Sleeve for Canned Motor Pump

Contacteer me voor vrije steekproeven en coupons.

Whatsapp:0086 18588475571

wechatten: 0086 18588475571

Skypen: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

xProductdetails

| Naam | Aangepaste keramische glijdende lager | Categorie | Keramische pomplager |

|---|---|---|---|

| Materiaal | Drukloos gesinterd siliciumcarbide/zirconia | Maat | Aangepast, volgens de tekeningen |

| Gebruik | ingeblikte motorpomp | Pakket | Schuim+doos |

| trefwoord | ingeblikte motorpomplager | Type | cruciaal transmissiedeel |

| Markeren | SiC sliding bearing for motor pump,ceramic sliding bearing sleeve,canned motor pump SiC bearing |

||

Productomschrijving

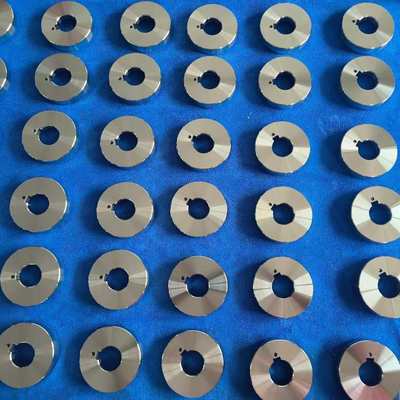

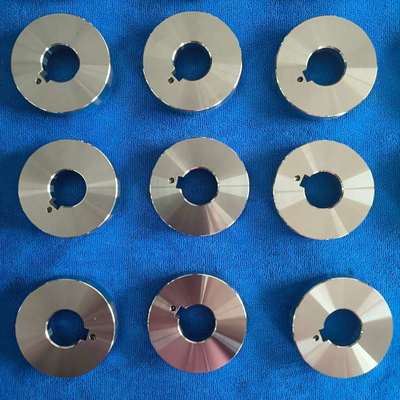

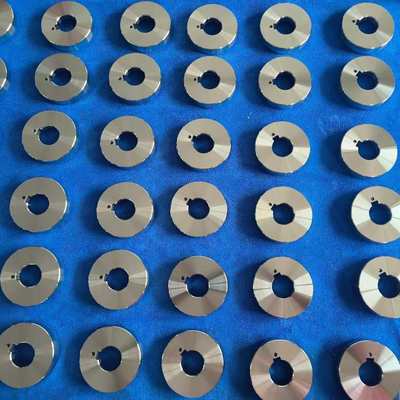

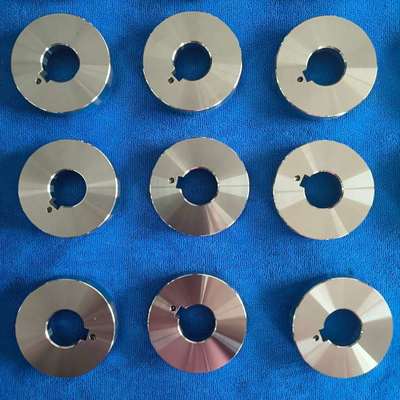

Sliding Bearing SiC Sleeve for Canned Motor Pump

Silicon Carbide (SiC) Sleeve and Thrust Disc Assembly

The Sleeve and Thrust Disc Assembly is a critical component of sliding bearings, serving as both the support and rotational unit in canned motor pumps. Silicon carbide (SSiC) is renowned for its outstanding corrosion resistance, wear resistance, and superior material properties, making it an ideal sliding bearing material for such pumps.

Key Features

- Superior Wear Resistance: High hardness and low friction coefficient of SiC (SSiC/SiC) ensure extended service life.

- Corrosion Resistance: Immune to acids, alkalis, and high-temperature fluids, ideal for aggressive media.

- Thermal Stability: Low thermal expansion maintains dimensional accuracy under high-speed rotation.

- Customizable: Available in standard or integrated designs to fit various pump models.

Typical Uses

- Chemical process pumps, nuclear coolant systems

- High-purity fluid transfer (e.g., semiconductor-grade chemicals)

- Sealless solutions for extreme pressure/temperature conditions

Main Applications of Canned Motor Pump

1. The canned motor pump can be used in common corrosive conditions, such as with inorganic matter, acid, alkaline and salt media. In such conditions, SSiC (sintered) is the standard sliding bearing material.

2. The canned motor pump can be used in common corrosive conditions with media that is prone to vaporization.

Key Properties of Pressureless Sintered Silicon Carbide

| Max Temperature | Up to 1650℃ |

| Density | 3.15-3.18 g/cm³ |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410 GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

Product Images

Our Factory and Processing Capabilities

We operate three factories in China to meet diverse customer requirements, equipped with advanced pressing, sintering and processing machinery.

Geadviseerde Producten